Certificates:ISO9001 & SGS

MOQ:Any MOQ

Payment Terms:T/T Or Negotiate

Delivery Time: 3-5 working days but depends on quantity

Samples:Samples can be provided but customers need to bear the freight cost

If you have any questions, please feel free to contact us.

Product Description

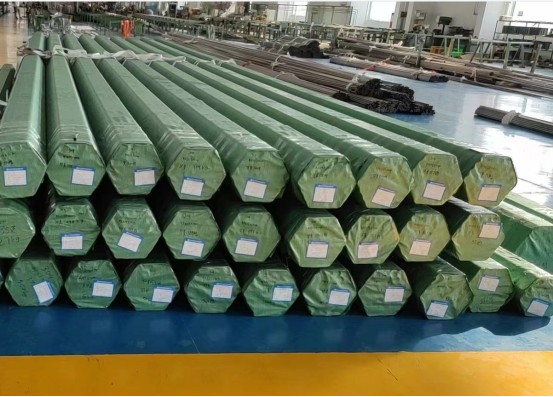

Incoloy Tube is a Ni-Cr alloy that has superior ability to maintain a stable structure during prolonged exposure to high temperatures. ASTM B163 Incoloy Tubing is an alloy composed of nickel-iron-chromium, with additions of molybdenum and copper in small proportions.Incoloy High-Pressure Tube is supplied bright annealed in the outside diameter range 6 –42 mm (0.25 in –1.625 in) and wall thickness 0.89 –5.00 mm (0.035 in –0.197 in). Incoloy seamless tube is available in straight lengths and coils. Incoloy coiled and straight length tubing are supplied annealed and solution annealed. Incoloy Instrumentation Tubes Stock will be available for most common sizes.

Product parameters

Product characteristics

High temperature strength

High creep rupture strength

Resistant to oxidation and carburization in high temperature environments

Good corrosion resistance in many acidic environments

Good resistance to many sulfur-containing atmospheres

Product applications

Industrial furnace components and equipment

Petrochemical and chemical processing

Equipment for Heat-Treating

Pressure vessels and heat exchangers

Hydrocarbon cracking

Chemical composition

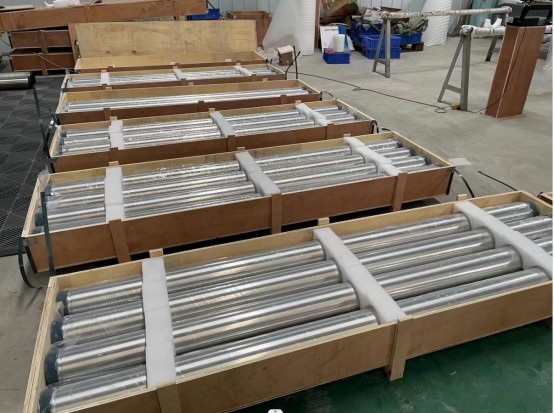

Shipping

FAQS

Q: Can we visit your factory?

A: Warmly welcome once we have your schedule we will pick you up.

Q: Can I get samples before order?

A: Yes, of course. we can produce by your samples.

Q:what is your delivery time?

A: Our delivery time is about one week, but timing is according to the quantity.

Q:What are your payment terms?

A: Our usual payment methods are T/T, but payment methods can be negotiated and customized with customers.

Q:What do your factory do regarding quality control?

A: We have obtained ISO, EN10204 3.1/3.2 and other certifications. From materials to products, we check every process to maintain good quality.

Q:How do you make our business long-term and good relationship?

A:We keep good quality and competitive price to ensure our customers benefit; We respect every customer as our friend and we sincerely do business and make friends with them. No matter where they come from.

Q:How about MOQ?

A: The MOQ is not limited, which can be customized according to customer requirements. Please feel free to leave us message if you have any question about us and our products.

Q:How about the shipping and packing?

1) About the small package, usually, the weight is not large than 70kg, we send it by DHL ,Fedex,UPS.

2) About the large package of more than 100kg, we send them by air.

3) For More than 100kg, we send it to the customer by air or by sea, if the customer needs it urgently, we will send it by air. if not needed urgently, we will send by sea, the freight cost will be more economic.

4) Anyway, we will choose the most economic and fast delivery way for customers.

Q:How do I place the order?

A: When you are satisfied with our quotation, we will offer the Proforma Invoice for your confirmation. Trade assurance is also acceptable.

After we received your prepayment, we will start to manufacture.

View More Products

Message

MESSAGE